QUALITY & MATERIALS

we work with

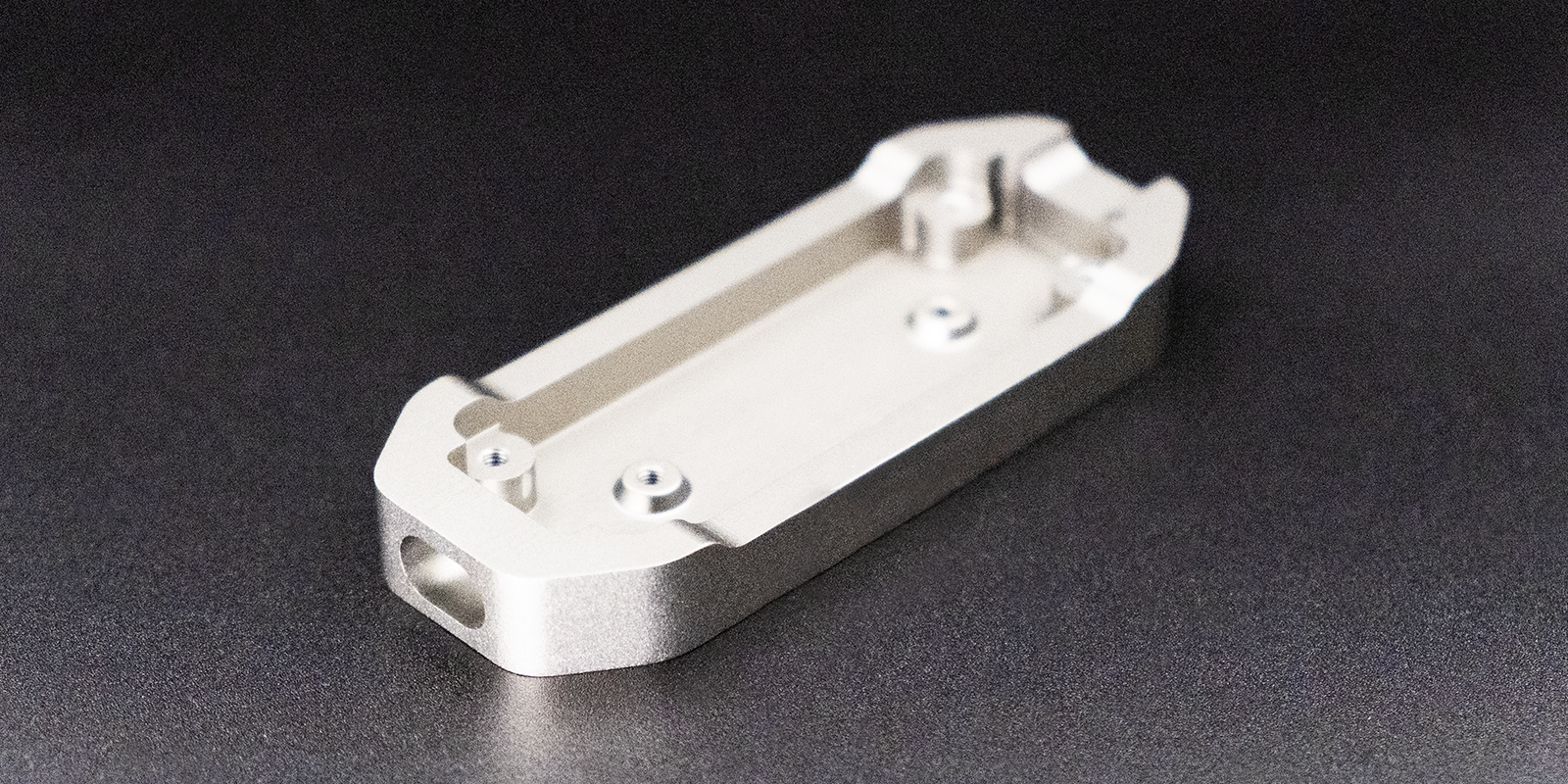

7075 aluminum is a cold-treated forging alloy, one of the most powerful alloys for commercial use. Tight structure, strong corrosion resistance and good mechanical properties. It's best for aviation and marine applications.

We use 7075 grade aluminum in all our products. CNC machining, bead blasting and anodizing it for additional strength, corrosion resistance and looks!

Polycarbonate also known as PC plastic, is a polymer containing carbonate groups in the molecular chain. It is colorless and transparent. Compared with the performance close to polymethyl methacrylate, polycarbonate has good impact resistance, high refractive index, good processing properties, and UL94 V-2 level flame retardant performance without additives.

All glass and visors in our devices are cnc machined out of a single block of polycarbon. We use PC plastic for greater scratch-resistance, polish it by hand and finish with additional vapor polishing process to achieve maximum transparency and smoothness.

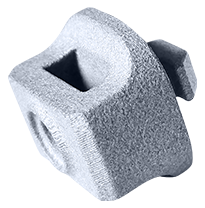

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) allows us to produce functional nylon prototypes and end-use production parts.

Final parts exhibit quality surface finishes, fine resolution, and consistent mechanical properties. The MJF process is used for mechanical (e.g. prototypes, articulated objects, geared systems), electrical, medical and automotive purposes.

We manufacture our parts according to strict manufacturing standards. For MJF, manufacturing with dimensional accuracy of ±0.3mm or 0.4%.

We use PA12 HP Nylon to create mounts and all sorts of practical brackets.

Thanks to our custom made PCBs everything we do works as expected! We develop our circuit boards using the highest quality electronic components. We do not skimp on copper plating, additional decorative layers and dedicated, custom graphics to give our products unique look and exceptional aesthetics.

TheRadSeries PCBs are a crutial part of the design! Yeah... we love it... you deserve it!